21Century Co. Ltd. introduced a mass-production laser processing device using a Galvano scanner that includes an active-controlled laser beam expander using ultra-high lasers. They order and manufacture ultra-precision laser processors, carbide cutting tools, MCT TOOLING, carbide precision molds, automated precision parts, and measuring gauges.

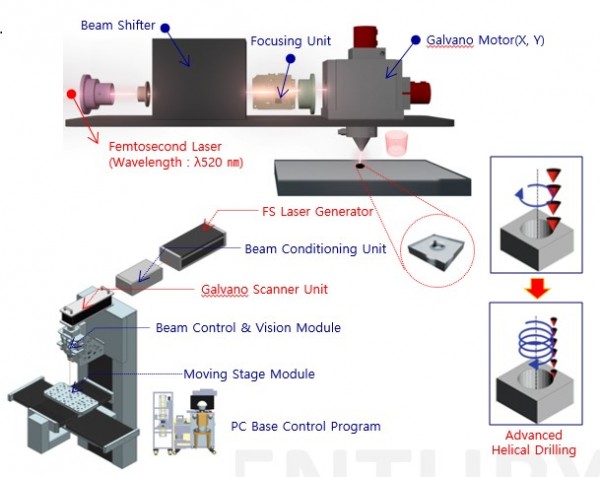

This device can improve the quality and productivity of ultra-precision holes by improving the quality of the metal processing object and speeding up the processing. When forming 10-200 micrometre micro-holes, the quality is enhanced by improving the roundness, cylindricity, and surface roughness of the inner wall surface.

Melt protrusions, surface curvature, and fragile particles were minimized by replacing the existing nanosecond laser with an ultra-high laser. Next, consistent roundness and high processing speeds were retained through applying a Galvano scanner with an active control laser beam expander.

In addition, while minimizing the deviation between the micro-hole diameter of the laser beam incident surface and the output surface, chamfering or rounding of the micro-hole edge of the laser beam incident surface (Hole + Chamfering or Rounding) is done simultaneously.

In particular, this device is utilized to form dozens to millions of microholes on vacuum plates, which are used for absorbing and transporting thin film sheets (ceramic, metal, coating films, etc.) or sequentially stacking them in exact locations. This prevents the pressing and tearing of thin-film sheets at the location around the hole.

It is expected to bring innovative changes to the stacking process facilities of multi-layer electronic components such as multi-layer ceramic capacitors, multi-layer ceramic varistors, and multi-layer ceramic actuators, as well as to multi-layer process facilities for manufacturing secondary batteries and multi-layer batteries used in various electronic devices, including electric vehicles.

An executive from 21 Century Co. Ltd. said, “The quality of the vacuum plate is a prerequisite for stacking thin film sheets. It can be applied to all fields that require micro ultra-precision holes.”

Media Contact

Company Name: 21CENTURY CO., LTD.

Contact Person: Marketing team

Email: Send Email

City: Hwasung-city

State: Seoul

Country: South Korea

Website: http://en.21t.co.kr/

Information contained on this page is provided by an independent third-party content provider. Frankly and this Site make no warranties or representations in connection therewith. If you are affiliated with this page and would like it removed please contact pressreleases@franklymedia.com