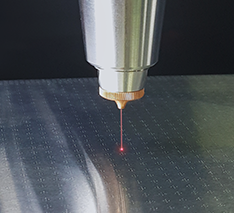

It is a method of processing by using a laser when processing micro holes, and it is possible to process the size of micro holes up to Φ0.03mm. The shape of the fine hole can also be deformed. (Round, oval, square, etc.)

• Name

VACUUM PLATE

• Composition

Special steel used besidesSKD11

• Applications

For cutting and laminating ceramic and electrode sheets (0.8um thick) when MLCC manufactured