21st Century (CEO Kim Seong-hwan) was founded in May 1996, and now, based on the experience and innovative ideas accumulated over the years, super-precision laser processing, carbide cutting tools, carbide cutters, carbide precision molds, automated precision parts, etc. It is a small business

The company made cutting tool tooling as its main business in the early days of its founding. Tooling is designing which tools and how many to use to machine which parts. Cutting conditions suitable for mass production systems were designed according to customer needs, such as automobiles, and the cutting tools were delivered after undergoing process tests.

21st Century was recognized as a tooling company that provides the highest quality automotive parts while minimizing processes. However, sales were not sustainable. This is because the first order for cutting tools was received, but the second and third orders were pushed to other companies due to fierce price competition. A new growth engine was needed.

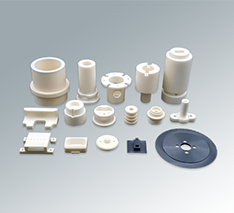

So, in 1998, the company shifted its focus from auto parts tooling to electrical and electronic/semiconductor parts. It has developed a differentiated processing technology that is universal and has improved precision compared to existing products to create automated precision parts. At that time, the IMF foreign exchange crisis was a time when good and bad companies were being sorted out, so the precision mold processing technology of the 21st century stood out, and in 2000, it started to receive orders from large companies in the electrical, electronic and semiconductor fields. Also, they were not satisfied with the ㎛ hole processing technology using a drill. In the 2000s, as electronic parts became smaller and more integrated, it was predicted that in the near future, the existing drills would reach a limit in machining holes of 30㎛ or less.

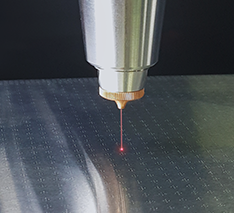

The company took on a new challenge again in 2003. In order to overcome the limitations of the existing physical processing technology, we started to develop processing technology using laser characteristics. Laser equipment, which was rare in the Korean processing equipment field, was imported from Germany and the characteristics of the equipment were tested for about a year. At the time, when annual sales were in the 1 billion won range, 1 billion won was boldly invested in R&D.

In the 21st century, thanks to such investment in technology development, patents were successively obtained for ‘carbide cutter technology’ in February 2005 and ‘laser-based drilling method for electric jig’ in March 2005. After that, patents such as ‘Laser-using polycrystalline diamond (PCD) chip breaker processing technology’ (March 2006) in March 2006 and ‘PCD chip breaker shape processing insert using laser’ (April 2008) in April 2008 Acquired, established a unique position in the field of ultra-precision laser processing technology.

The company entered the overseas market in 2011 and is doing business with domestic companies as well as Japanese companies. In particular, MTE TOOLING in 2013 and MPPI in the Philippines in 2017 were acquired and merged with local companies’ manpower and know-how, thereby laying the foundation for global management.

In 2017, the company was recognized externally for its excellent grinding technology, such as ‘Ultra-precision cutter manufacturing technology using electrolytic in-process dressing (ELID) grinding processing technology’ was selected as a new technology (NET) by the Ministry of Trade, Industry and Energy in 2017. This technology is evaluated to have the effect of reducing costs because it can replace the import of expensive Japanese grinding equipment and process ultra-thin material cutters.

The company plans to secure ultra-precision cutter technology by convergence of ELID technology and laser technology this year, and build a position as a global top ultra-precision cutter brand next year. To this end, an expert from LG Saenggiwon is recruited as the CTO and joint development with the Institute of Machinery and Materials begins. In the future, it will also localize a laser oscillation device and advance into the ultra-precision cutter market such as a medical scalpel and razor for the general public with its original laser processing technology.

“To overcome the limitations of cutting tools, we boldly challenged laser technology and succeeded, and we plan to overcome the limitations of laser technology this time.”

Kim Seong-hwan, CEO of the 21st century, said this while emphasizing that “the core of future parts and materials processing technology is laser technology.” The advantage of laser equipment is that it can perform ultra-precision processing and welding, and customers can digest various processes that were not possible with existing equipment, such as 3D processing technology.

CEO Kim is reorganizing the organization with the goal of achieving 60 billion won in sales and listing in 2020 along with efforts to develop technology to respond to customer demand in advance. I also received management consulting for 6 months last year. The technology research center and management planning team were moved to downtown Hwaseong, Gyeonggi-do in May, and 8 high-level personnel in finance and research were hired, and the plan is to continue to fill them.

He emphasizes to his employees, ‘Let’s enjoy change’. This is the belief that I have brought since I entered the front line of entrepreneurship at the age of 26. It started with 7-8 employees at the beginning of its founding, and has grown into a 30 billion won company with 120 people using three core technologies: ultra-precision laser processing, carbide cutter, and carbide precision mold. The strong desire for corporate growth is being filled with constant technological change.